Designing projects with complex geometry presents unique challenges matched only by the unique opportunities for innovative engineering they provide. MKA’s experience designing complex forms extends back to our experience with thin-shell concrete in the 1950s; by using modern tools, we can realize designs that would have been inconceivable in that era. Whether swooping and curved or angular and faceted, grand in scale or finely detailed, these projects require an individually tailored approach to ensure a successful outcome.

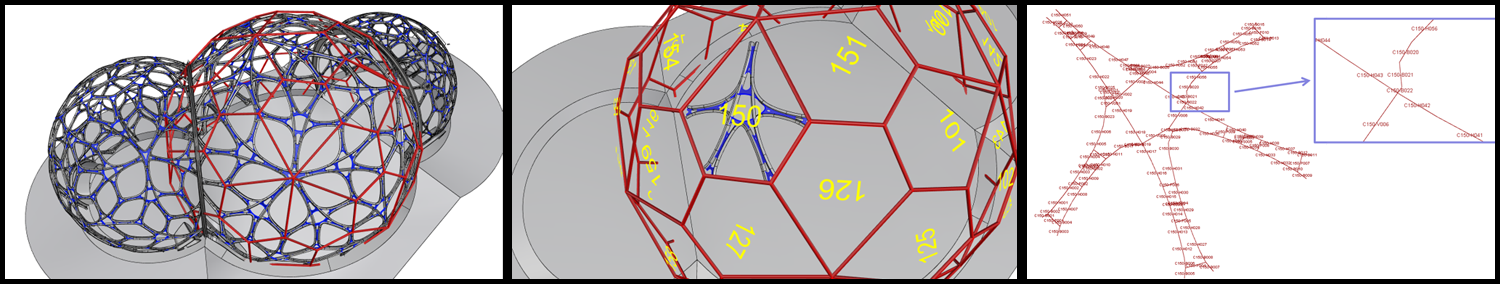

Essentially, a single pentagon of set dimensions is arrayed 60 times to form a complete sphere.

Key to project success is MKA’s understanding of our architectural clients’ creative design processes and the capabilities of the fabricators and erectors who will execute the final design. MKA prefers to develop custom design workflows and tools for each project to best fit that project’s specific requirements.

As with more conventional projects, communication and collaboration are crucial. MKA favors working directly with an architect’s design model to minimize translation errors. Using cutting-edge parametric design tools, the structure is fitted to the architectural form when possible, supporting it and providing an integral part of comprehensive sculptural quality. Overall, decisions on design iterations can be more easily made by communicating the structural design back into the architect’s model.

Image credit: Chad Davies | !melk

MKA brings a deep understanding of fabrication and erection to every design, developed in long collaboration with our construction partners. When developing a structural design, considerations of fabrication techniques, material limitations, construction sequencing, and cost are foremost. Minor rationalizations to an architectural design can significantly impact project cost and viability, and searching out these opportunities is a key part of our service.

Want to learn more?

Contact Robert Baxter PE, SE, to start a conversation about how MKA can transform your project with complex geometry from idea to reality.